Network Rail’s Supply Chain Operations division wanted to replace their paper-based sign-in and induction process with a new digital solution that could be trialled on seven depots, for a potential future rollout across 44 UK sites.

Network Rail’s primary requirements were for:

Over a nine-month period, we worked closely with key stakeholders at Network Rail to design, trial, and implement a new web-based interactive system across the seven sites.

The project made use of the latest gaming technology, which we tailored to create an immersive user experience.

“The feedback on the project has been fantastic and this is a credit to how hard D2 has worked with excellent attention to detail, ensuring that this is a program that is accessible by all.”

Stephen Shields, Network Rail Workforce Health, Safety and Environment Advisor

Network Rail had previously commissioned us to develop a fully interactive 3D virtual reality ballast cleaner operative training system. They had been very impressed with user friendliness and authenticity of the end product. So, when they needed help to improve their depot induction training and sign-in process, we were their clear choice.

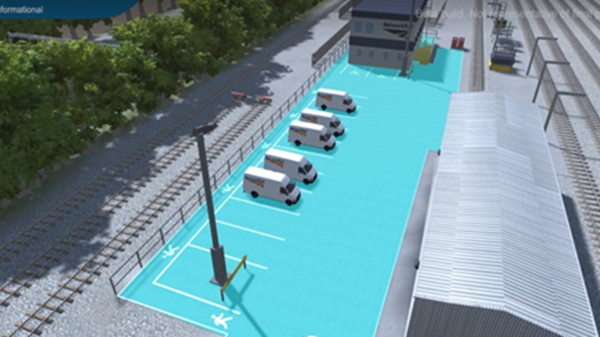

Network Rail selected seven sites around Crewe in Cheshire, and Sandiacre in Derbyshire, to trial the new solution. The concept was to create a single common system with the agility to suit different layouts and functions. Each site needed to be modelled in a fully virtual 3D world to a high level of accuracy. So, our first task comprised visiting each site to gain data relating to their footprint and function, and to collect large amounts of imagery.

Next, we collaborated with Network Rail to identify and quantify key content and topics, along with the interactive elements and knowledge checks that were to be included in the system. 17 outlined modules ranged from key routes and locations on site, PPE information, working from height guidelines, and lifesaving rules checks.

To create bespoke and relevant experiences for different users, the induction was split into two categories. A general induction for visitors contained essential basic health and safety information. An advanced induction for staff and contractors covered more specific and detailed information about certain aspects of working at depots.

With the sites identified, and content defined, we were ready to start putting the system together. Using game development technology, we built seven unique 3D environments that represented each depot to a high level of accuracy. We then built in the basic elements such as system controls, cameras, navigation, and interactivity.

We now faced the biggest challenge of the project; developing a logic system that implemented the modules and content once but applied it to all seven depots and their different environments. This was critical because creating separate bespoke modules for each site would make future system updates time consuming. A legacy solution was required.

In response to this, our developers created a module management component within the system that held the core module information and interactive logic elements. By incorporating geographically mapped event markers, we enabled the component to correctly overlay the induction modules onto any depot environment we loaded into it.

The result was a single set of common modules that, if updated, could replicate very quickly across all depots, simultaneously. This feature also enables us to add more depots and environments to the system with very little effort.

Once the environments and modules were complete, D2 developed a full web-based management system which would host the inductions and take care of the data flow. This would allow Network Rail to report on induction completion statistics, view depot footfall and visitor statistics, and run emergency rollcalls on each depot. Using WebGL graphics rendering technology, this user interface would also be capable of running each depot induction through most modern web browsers and devices, ensuring a high level of accessibility for all users of the system.

Currently being deployed to seven depots, the system has been well received and Network Rail is currently evaluating how to manage a rollout across all 44 of their UK depots. We have identified potential enhancements to improve flexibility for more complex sites. Other improvements will include lidar site scans to improve accuracy and accelerate location specific system development turnaround times.

“This project has been designed from the outset to improve how we manage our inductions, which will enable us to keep our workforce, contractors, and visitors safe when they visit and work at our depots.”

Stephen Shields, Network Rail Workforce Health, Safety and Environment Advisor